Navigating the Future: Trends Shaping the Supply Chain in 2025

Related Articles: Navigating the Future: Trends Shaping the Supply Chain in 2025

Introduction

With great pleasure, we will explore the intriguing topic related to Navigating the Future: Trends Shaping the Supply Chain in 2025. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Navigating the Future: Trends Shaping the Supply Chain in 2025

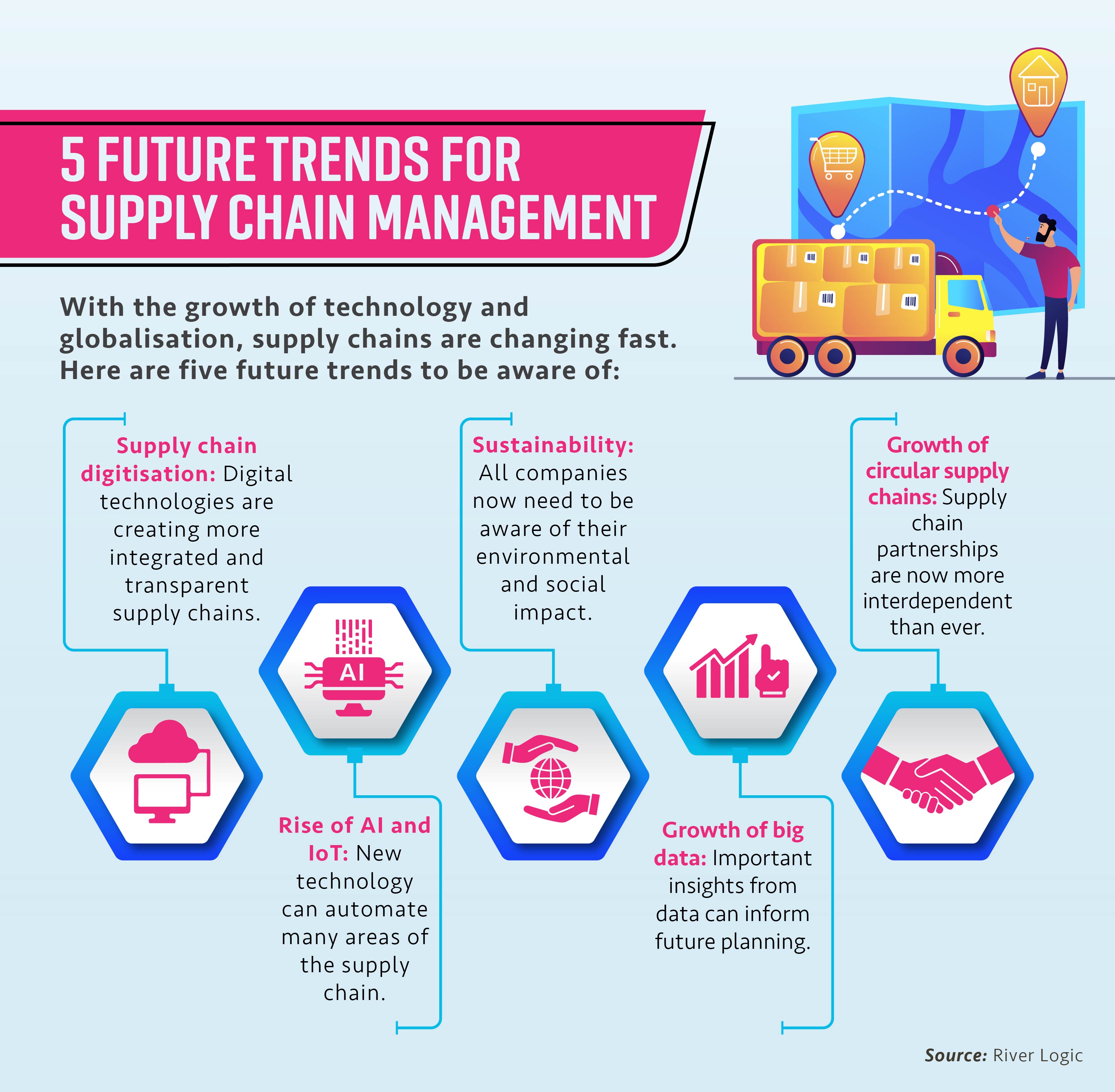

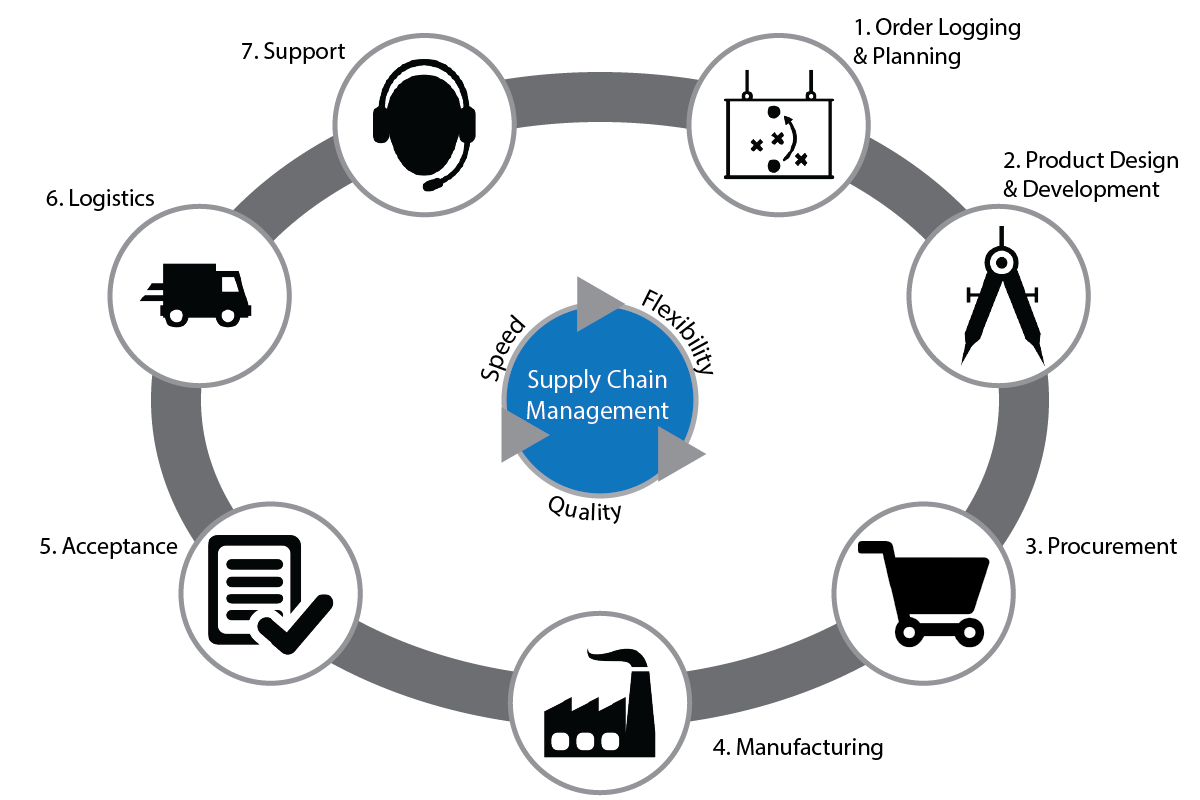

The supply chain, the intricate network that delivers goods and services to consumers, is undergoing a profound transformation. Fueled by technological advancements, evolving consumer expectations, and global economic shifts, the landscape of supply chain management is being redefined. As we look towards 2025, a clear understanding of the emerging trends is paramount for businesses to remain competitive and resilient.

This article delves into the key trends shaping the supply chain in 2025, exploring their implications and providing insights for businesses to navigate the evolving landscape.

1. The Rise of Hyper-Personalization and Mass Customization

Gone are the days of one-size-fits-all products. Consumers are demanding personalized experiences, leading to a surge in mass customization. This trend requires supply chains to become more agile and flexible, capable of tailoring products and services to individual needs.

-

Implications:

- Increased product variety: Businesses will need to manage a wider range of SKUs, requiring sophisticated inventory management systems and optimized logistics.

- Dynamic production processes: Manufacturing processes will need to adapt quickly to changing customer demands, necessitating flexible automation and modular production lines.

- Enhanced data utilization: Real-time data analysis will become crucial for understanding customer preferences and optimizing production and delivery processes.

2. The Power of Data and Analytics

Data is the lifeblood of the modern supply chain. Advanced analytics tools and artificial intelligence (AI) are transforming how businesses gather, analyze, and act upon data. This allows for more informed decision-making, improved forecasting, and proactive risk management.

-

Implications:

- Predictive analytics: Data-driven insights can anticipate demand fluctuations, optimize inventory levels, and prevent stockouts.

- Real-time visibility: Tracking goods and resources in real-time provides greater transparency and control over the supply chain.

- Enhanced risk management: AI algorithms can identify potential disruptions and vulnerabilities, enabling timely interventions and mitigating risks.

3. The Embrace of Automation and Robotics

Automation and robotics are revolutionizing the supply chain, streamlining processes and increasing efficiency. From warehouse automation to autonomous delivery vehicles, technology is automating tasks traditionally performed by humans.

-

Implications:

- Increased efficiency: Automation reduces human error, improves productivity, and minimizes downtime.

- Cost optimization: By automating repetitive tasks, businesses can achieve significant cost savings and improve profitability.

- Enhanced safety: Robotics can perform dangerous or physically demanding tasks, creating a safer working environment.

4. The Integration of Blockchain Technology

Blockchain technology offers a secure and transparent platform for managing supply chains, enhancing trust and traceability. It enables real-time tracking of goods, verifies product authenticity, and reduces fraud.

-

Implications:

- Improved transparency: Blockchain provides a shared, immutable record of transactions, increasing transparency and accountability throughout the supply chain.

- Enhanced security: The decentralized nature of blockchain makes it highly resistant to tampering and data breaches.

- Streamlined processes: Blockchain can automate tasks like documentation, payments, and verification, reducing manual effort and errors.

5. The Rise of Sustainable Supply Chains

Consumers are increasingly demanding environmentally and socially responsible products. Businesses are responding by adopting sustainable practices throughout their supply chains, focusing on reducing their environmental footprint and promoting ethical sourcing.

-

Implications:

- Green logistics: Businesses are prioritizing sustainable transportation options, reducing emissions and fuel consumption.

- Circular economy: Companies are embracing circular economy principles, minimizing waste and maximizing resource utilization.

- Ethical sourcing: Businesses are ensuring their suppliers adhere to ethical labor practices and environmental standards.

6. The Importance of Resilience and Agility

Global events, such as pandemics and geopolitical tensions, have highlighted the need for resilient and agile supply chains. Businesses are adopting strategies to mitigate disruptions, diversify sourcing, and adapt to changing market conditions.

-

Implications:

- Supply chain diversification: Reducing reliance on single suppliers and establishing alternative sourcing options enhances resilience.

- Nearshoring and reshoring: Bringing production closer to customers reduces transportation costs and lead times.

- Advanced forecasting and planning: Utilizing sophisticated analytics and simulation tools to anticipate and respond to disruptions.

7. The Power of Collaboration and Partnerships

Collaboration and partnerships are becoming increasingly crucial for success in the complex supply chain landscape. Businesses are forging strategic alliances to share resources, leverage expertise, and create more efficient and resilient networks.

-

Implications:

- Shared resources and expertise: Collaborative platforms allow businesses to access specialized knowledge and resources they may not possess internally.

- Joint innovation: Partnerships foster innovation and accelerate the development of new technologies and solutions.

- Increased market reach: Collaborating with complementary businesses can expand market reach and access new customer segments.

8. The Growing Influence of Digital Twins

Digital twins are virtual representations of physical assets, allowing for simulation and analysis of various scenarios. In supply chain management, digital twins can optimize warehouse layouts, improve logistics, and predict potential disruptions.

-

Implications:

- Enhanced planning and optimization: Digital twins enable testing and optimization of various scenarios before implementing changes in the physical world.

- Predictive maintenance: By simulating asset behavior, digital twins can identify potential failures and schedule preventive maintenance.

- Improved decision-making: Digital twins provide real-time insights into asset performance, enabling more informed decisions regarding operations and resource allocation.

Related Searches:

- Supply Chain Management Trends 2025: This search explores the broader trends shaping the future of supply chain management, encompassing technological advancements, sustainability, and organizational changes.

- Supply Chain Technology Trends 2025: This search focuses on specific technologies driving innovation in the supply chain, such as artificial intelligence, blockchain, and automation.

- Future of Supply Chain 2025: This search explores the long-term vision for the supply chain, considering its role in a rapidly changing world and the impact of emerging technologies.

- Supply Chain Disruption 2025: This search focuses on the challenges and risks facing supply chains, including geopolitical instability, climate change, and technological disruptions.

- Supply Chain Sustainability 2025: This search explores the increasing emphasis on sustainability in the supply chain, including environmental impact, ethical sourcing, and social responsibility.

- Supply Chain Automation 2025: This search delves into the role of automation and robotics in transforming supply chain processes, increasing efficiency, and reducing costs.

- Supply Chain Analytics 2025: This search focuses on the use of data analytics and artificial intelligence to improve decision-making, optimize operations, and enhance supply chain visibility.

- Supply Chain Resilience 2025: This search explores strategies for building resilient supply chains, mitigating disruptions, and adapting to changing market conditions.

FAQs:

Q: What are the biggest challenges facing supply chains in 2025?

A: Supply chains in 2025 will face several challenges, including:

- Geopolitical instability: Global conflicts and trade tensions can disrupt supply chains and create volatility.

- Climate change: Extreme weather events can disrupt transportation networks and impact production.

- Cybersecurity threats: Increasingly sophisticated cyberattacks can compromise data security and disrupt operations.

- Talent shortages: The demand for skilled workers in supply chain management is expected to increase, creating talent shortages.

- Consumer expectations: Consumers are demanding faster delivery, greater transparency, and personalized experiences, putting pressure on supply chains to adapt.

Q: How can businesses prepare for the trends shaping the supply chain in 2025?

A: Businesses can prepare for the future of supply chain by:

- Investing in technology: Embracing advanced technologies like AI, blockchain, and automation to improve efficiency and agility.

- Developing data-driven strategies: Utilizing data analytics to gain insights, optimize processes, and make informed decisions.

- Building a resilient supply chain: Diversifying sourcing, establishing contingency plans, and fostering strong relationships with suppliers.

- Embracing sustainability: Adopting environmentally and socially responsible practices throughout the supply chain.

- Cultivating a culture of innovation: Encouraging experimentation and collaboration to develop new solutions and stay ahead of the curve.

Tips:

- Prioritize data and analytics: Invest in tools and expertise to collect, analyze, and leverage data for informed decision-making.

- Embrace automation and robotics: Automate repetitive tasks and leverage robotics to improve efficiency and reduce costs.

- Foster collaboration and partnerships: Build strong relationships with suppliers, customers, and other stakeholders to create a more resilient and efficient network.

- Focus on sustainability: Incorporate sustainable practices throughout the supply chain, from sourcing to logistics and waste management.

- Stay informed and adaptable: Continuously monitor industry trends, adapt to changing market conditions, and be prepared to adjust strategies as needed.

Conclusion:

The supply chain in 2025 will be characterized by its dynamism, agility, and reliance on advanced technologies. Businesses must embrace these trends, adapting their strategies and operations to remain competitive and resilient. By investing in technology, fostering collaboration, and prioritizing sustainability, businesses can navigate the evolving landscape and unlock the full potential of the future supply chain.

Closure

Thus, we hope this article has provided valuable insights into Navigating the Future: Trends Shaping the Supply Chain in 2025. We thank you for taking the time to read this article. See you in our next article!